Since 1967 ADUE S.p.A. has been designing, manufacturing and installing syrup rooms (EASY.Room) for the preparation of all types of beverages: from remineralised, flavoured and alkaline water, CSDs, Hard Seltzers and juices, to flat, milk-based, energy, fantasy and functional drinks, to non-alcoholic beer.

Solutions consolidated by decades of experience, recognised by the market at an international level, and adapted from time to time to meet specific customer requirements, always guaranteeing maximum production flexibility, quality and safety of the finished product and a saving of natural resources, thanks to continuous R&D activity.

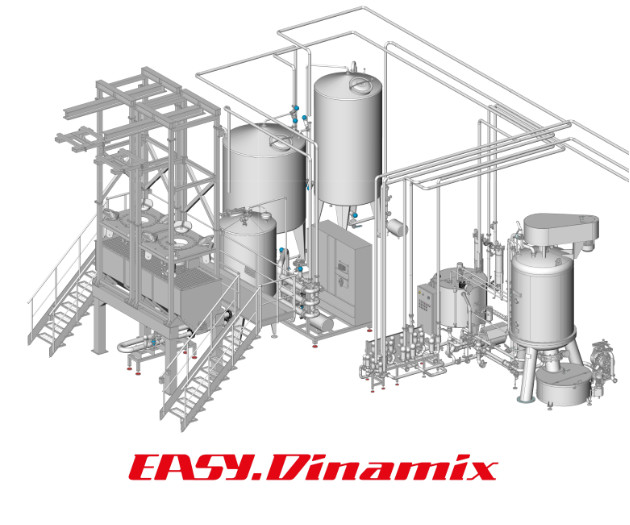

The dissolution of granulated sugar to obtain sugar syrup represents one of the fundamental steps in the preparation of all beverages. ADUE offers integrated systems for the reception, storage and transfer of granulated sugar and the continuous preparation of sugar syrup (EASY.Dinamix).

In addition to high precision (tolerance on the °Bx: ± 0.1°Bx), maximum production efficiency (with reduced dissolution times thanks to the use of a specific diffuser nozzle and a Venturi system), maximum energy saving (thanks to the integrated HTST pasteurisation system with heat recovery) and minimum space requirements (thanks to the compact configuration, with horizontal baskets for TRISLOT filtration) are guaranteed. Specific measures (e.g. the recovery of the water/sugar syrup pushing phases when emptying the kieselghur filters) allow the syrup preparation process to be optimised.

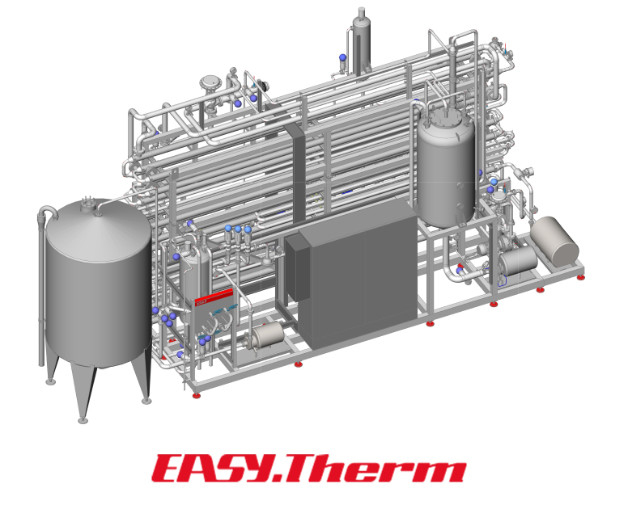

For optimal quality and safety, the finished drink, before filling, may require physical and microbiological stabilisation which ADUE systems achieve through three distinct phases: deaeration, homogenisation and pasteurisation.

ADUE’s EASY.Therm pasteurisation units include plate or tube heat exchangers, depending on the type of product (clear, viscous, with pieces) and the filling technology.

A special recirculation system guarantees energy recovery of over 90%.

The aseptic pasteuriser (which can be integrated with a vacuum deaerator complete with aroma recovery, homogeniser and aseptic tank) is designed to recover 80% of the steam used during the sterilisation phase and to reduce product losses during the water pushing phases by 20%.

A consolidated and transversal experience in all phases of beverage preparation, which ADUE makes available to its customers by formulating tailor-made, automated and eco-sustain solutions: Our experience, Your beverage!.

For more information contact us: info@adue.it – www.adue.it – Phone +39 0521 505411