A DUE technicians are able to best size the filtration units and the column filters, taking into account the following factors: type and concentration of compound to be removed, temperature, pressure and pH of the water stream, using self-cleaning, dual media or Carbon filters, Ultra-Filtration or Cartridge filters.

Adsorption on specific filtration beds (like active carbon, pirilusite, alumina, ecc.) are used to remove Chlorine, ions, halogenated organic compounds, pesticide, heavy metals and other contaminants harmful to health, as well as unpleasant smells and tastes.

Clarification trough lamella settlers or biological oxidizing treatment can be added in special water treatment units.

Ultrafiltration (UF) is a pressure-driven separation process suitable for retaining biomolecules, bacteria, viruses, polymers, colloidal particles and dissolved organics (partially).

Water filtration by means of UltraFiltration (EASY.UF) removes suspended solids, colloids and most of bacteria. UF is often used as pre-treatment stage before the Reverse Osmosis system, enhancing its productivity.

Cartridge filters are modular filters placed into housing, used to eliminate particles and, to a lesser extent, chemicals contained in the water.

Filtration takes place under pressure: unwanted particles and pollutants are retained by the filter, allowing the clarification of water. The filter undergoes a progressive saturation (which is measured by the pressure difference between the inlet and the outlet), until it is necessary to replace it by new ones, due to energy costs.

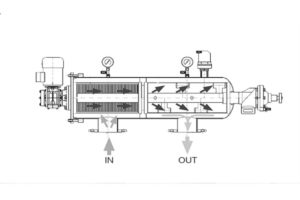

Self-cleaning filter

Recommended for “dirty” wells. In some cases (depending on the raw water features) it can replace the sand filter.

Internal Scraper with suction nozzle, equipped with gearbox.

Flowrate from 10.000 l/h to 100.000 l/h each unit.

Dual Media filter or Sand filter

Dual Media Filter for mechanical removal of coarse particles from water by pressure filtration.

This pre-filtration is also used for: reduction of turbidity; reduction of iron and manganese; reduction of fluorine (through a special filter bed); pH increase (through special filter bed).

It increases the working autonomy of the cartridge filters and reverse osmosis placed downstream.

Working flow rate between 10,000 l/h up to 60,000 l/h for each filter unit.

Filter bed composed of several layers of quartzite and/or anthracite (or other particular filter beds) in such a way as to be able to achieve a complete and homogenous filtration of the water.

Uniform distribution of water through special nozzles.

The tanks are designed to ensure optimal filtration speed (6 -12 m3/h/m2) according to the quality of the water to be treated.

The system allows easy backwashing once the set differential pressure has been reached (usually 0.6 bar), restoring the integrity of the filter bed with limited water consumption.

Carbon filter

Mainly used to remove the chlorine deriving from the initial disinfection phase and also serves for the adsorption of odours, if any.

Used to protect the upstream Reverse Osmosis plants and to lower the residual chlorine below the legal limits prior to water bottling / production.

Uniform distribution of water through special nozzles.

Working flow rate between 10,000 l/h up to 60,000 l/h for each filter unit.

The tanks are designed to guarantee an optimal contact time (EBCT) in the range 6 ÷ 15 min depending on the quality of the water to be treated and the customer’s target specifications).

The system allows easy backwashing once the set differential pressure has been reached (typically 0.6 bar), restoring the integrity of the filter bed with limited water consumption.

Regeneration and sterilization system using hot water (95 °C) or low pressure steam (0.5 bar).

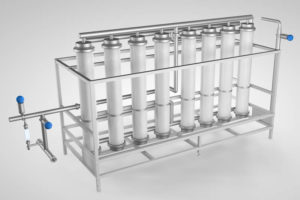

EASY.UF (Ultra Filtration)

Modular units consisting of inside-outside hollow fiber membranes, used to purify surface water or ground water from suspended solids, colloidal particles and all types of microorganisms such as bacteria, viruses, protozoa, germs and larvae.

Ultrafiltration is also used for the pre-treatment of tertiary purifier waste water.

Fully automatic unit equipped with PLC able to manage all production phases including backwash, CEB (cleaning enhanced backwash) and CIP.

Process parameters completely configurable from the operator panel.

Flowrate from 10,000 l/h to 100,000 l/h each unit.

Stand alone and compact unit, versatile and easy-to-clean, can be integrated into the existing systems.

Complete with ultrafiltered water storage tank and unit for preparing and dosing chemicals (soda, acid and disinfectant).

Automatic process control by PLC with managment of alarms and variables.

Cartridge filter

Cartridge filters for process water microfiltration.

Available in different filtration degrees (from 0,1 to 10 micron).

Used to preserve the integrity of reverse osmosis or for final microbiological filtration before bottling.

Can be sanitized either by heat or by chemical agents.

Possibility of backwashing to increase working autonomy.

Working flow rate between 500 l/h up to 100,000 l/h.

Cartridges available with standard international connections (C7 or DOE) and therefore interchangeable.

Availabile in materials suitable for hot washing and sterilization.

Possibility of using special high-performance single-cartridge filters, reduced overall dimensions and reduced operating costs.