ADUE, a company that has always been at the forefront in the construction of systems for the beverage industry, pays special attention to the operation and control of its machines.

All electrical panels are designed and built in compliance with current regulations, paying particular attention to the quality of the materials.

To make working methods simple and safe, ADUE makes use of the latest automation technology via state-of-the-art PLCs, programmed by its in-house staff using high-level languages.

For the management of the utilities in the field, remote stations are used to collect the signals locally and thus reduce the number of cables in the cable trays.

The remote stations and some process instruments, such as flow meters, solenoid valves, beverage analysers and frequency converters, are connected to the PLC via the latest field buses for a safe and accurate reading of measured quantities.

Particular attention is paid to the Human-Machine Interface (HMI) to make system control simple and safe.

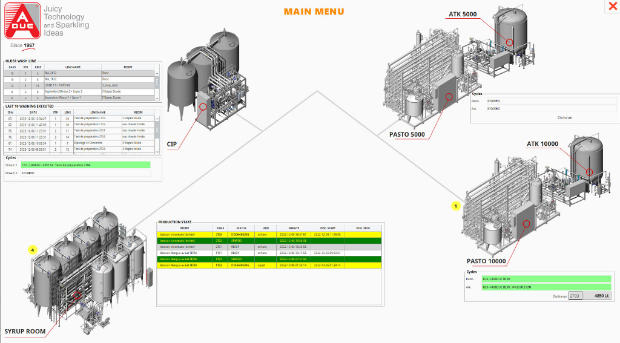

All the machines have an interface based on the same clear and intuitive graphic style, allowing simpler and faster learning.

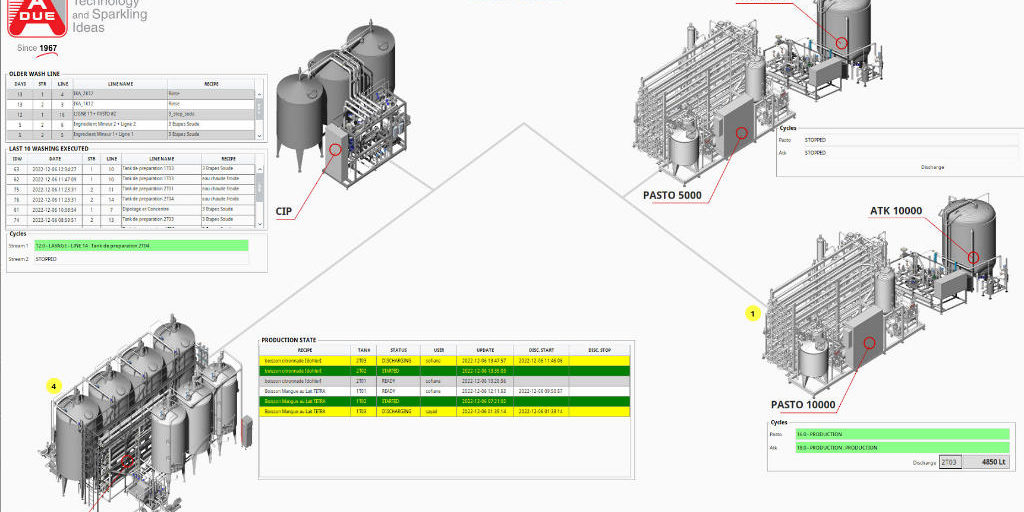

The state of the process is represented on high-definition screens, displaying all the utilities in the system and identifying, through the colouring of the graphics, the composition of the product in the tanks and pipes.

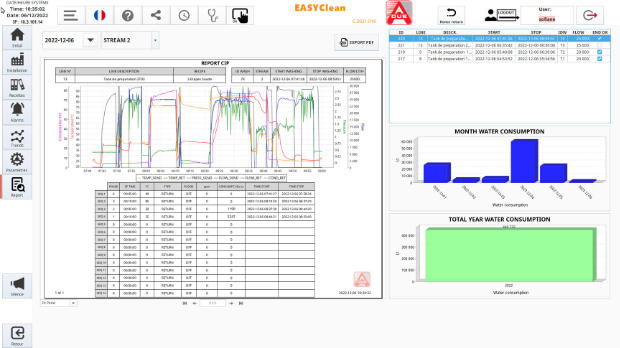

In addition to the real-time data displayed on the synoptic pages, it is possible to view a trend history of the most representative values by means of coloured graphs.

Wizards and graphical representations help operators to compose production recipes, select raw material workflows and check the correct dosage.

They are assisted in this through clear and comprehensive messages to minimise processing times.

All operations on the operator interface are managed by access control according to various levels, to which each user is associated. This enables safe management of the most critical operations, allowing only personnel with the required qualifications to control them.

Alarms, system messages, production reports and all operations carried out by the user are stored in a database archive, allowing the data collected to be consulted and traced at any time.

If there is a web connection, the operator can access a special chat page for remote assistance with an ADUE service operator.