The use of essential oil aromatic emulsions for drinks preparation is becoming increasingly frequent thus bringing a need for the bottling companies of small stand-alone plants to produce emulsions locally.

Having thoroughly examined all the issues related to the management of such sensitive ingredients, including the logistics and design of the entire plant, A DUE is pleased to present its solution, i.e. a flexible and reliable emulsion preparation process, thanks to which each bottler is able to produce its own aroma emulsions (citrus, pineapple, red fruit bases, etc.) on site.

It’s worth noting that essential oils are not water-soluble. So to make possible their use it is necessary to disperse them in the form of an emulsion. It should be performed in a proper manner to avoid such adverse effects as deterioration of aromas, oil/water stratification during storage or an oil “collar” formation inside the bottle containing the finished product.

The process developed by A DUE provides for three distinct steps.

Step 1: separate preparation of two semi-finished products: an oil phase, composed of essential oil and a particular additive rendering its specific weight similar to that of the aqueous phase; and an aqueous phase, composed of water and various additives (thickeners, antioxidants, dyes, preservatives, etc.), which acts as a support for the oil phase.

Step. 2: the two phases are subsequently mixed and pre-emulsified to reduce the size of the oil droplets under 10 microns.

Step 3: the pre-emulsion thus prepared is subjected to a double-stage high pressure homogenization to obtain a homogeneous and stable emulsion (the droplets are micronized down to less than 1 micron). This ensures not only homogeneity and physical stability of the final product over time, but also improves its organoleptic and nutritional properties.

The preparation process can be combined with the automated storage of different aromatic emulsions or the product can be sent to a weight filling line for drums (for cool storage).

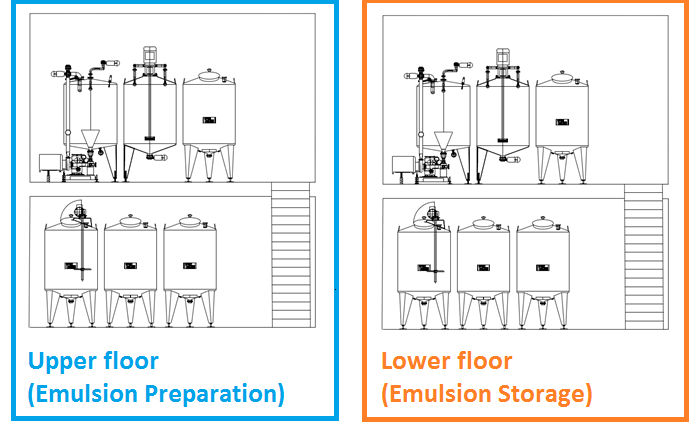

Considering that the product contained inside the preparation plant can be neither transferred nor recovered by means of water, its recovery occurs by gravity. Therefore, the plant lay-out provides for the preparation section in an elevated position compared to the storing and dosing section.

To learn more: info@adue.it or +39 0521 545011