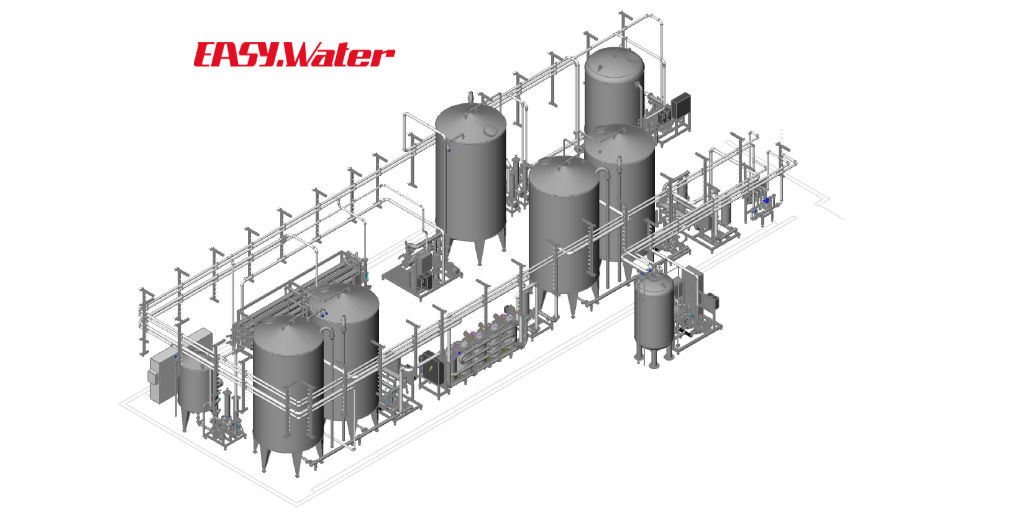

Water is the chief constituent in all drinks, therefore it must be treated with the utmost attention using top quality purification plants. A DUE designs, manufactures and installs high-tech Water Treatment Plants (EASY.Water) suitable to process well, surface or mains water in accordance with target specifications required for beverage production or mineralized water bottling.

Basically a WTP can be divided in four steps: preliminary chemical disinfection, pre-filtration (self-cleaning filters, dual media and carbon filters); final filtration (ultra-filtration, reverse osmosis, cartridge filters); final disinfection (UV-lamp, ozone, pasteurization).

The choice of the specific treatment depends on various factors.

For each type of beverage to process , A DUE has the appropriate technology to bring water parameters to the targeted chemical and physical values.

General parameters: total alkalinity (can affect the drink taste, standard limit value less than 50 mg/l of CaCO3), TDS, turbidity, pH (causes precipitation phenomena), hardness (between 15 and 50 °F for bottled water, while for juice and beverage production this value must be reduced).

Other parameters: Calcium (critical in the milk powder reconstitution process); Iron, Manganese and Aluminium (causing unwanted colourations and sediments, can be removed with catalytic means or Ozone oxidation); Ammonium (pollution index of the supply source); Barium and Strontium (combined with other elements form precipitates that clog the osmosis membranes); Arsenic (can be removed by adsorption/membrane/precipitation processes); Borates (toxic, eliminable by ion exchange and reverse osmosis); Chlorides (high content can cause corrosion phenomena); Sulphates (combined with particular bacteria can cause corrosion); Nitrates and Nitrites (indicate pollution of the supply source, can be removed by osmosis); Fluorides (harmful to health if exceed certain percentage, they can be removed with reverse osmosis, flocculation through hydrated aluminium salts and adsorption on a strong absorbent column); Bromides (problematic if the treatment involves ozonizing); Silica (high content can cause osmosis membrane clogging); Iron-reducing and sulphate-reducing bacteria (can cause the MIC Microbially Induced Corrosion phenomenon).

In conclusion, A DUE, thanks to its specific know-how, is able to support the customer already at the recipe conception phase, as well as throughout all the beverage production sequences, from the reception and management of the ingredients (including water), to the dosage and mixing of the same, up to the finished beverage treatments (carbonation, homogenization, pasteurization).