When drinking is also beneficial to our health: functional, energetic and flavoured waters and beverages, enriched with vitamins, minerals, antioxidants, natural extracts and flavours, spices, herbs or flowers, fruit juices. Appreciated not only for their taste, but also for their nutritional properties and beneficial effects on health: moisturizing, draining, purifying, digestive, toning and energizing.

For example, the flavoured waters, available in various fruit flavours or vegetable essences, can be enriched with minerals (Calcium, Magnesium, Zinc, Selenium, Potassium, etc.) or with vitamins (group B vitamins and C, PP, E, H , etc.).

Energy drinks, helpful to replenish water and electrolytes lost during physical activity, may contain mineral salts, sugar, maltodextrins, complex carbohydrates for the gradual release of energy as well as caffeine, taurine and water-soluble vitamins.

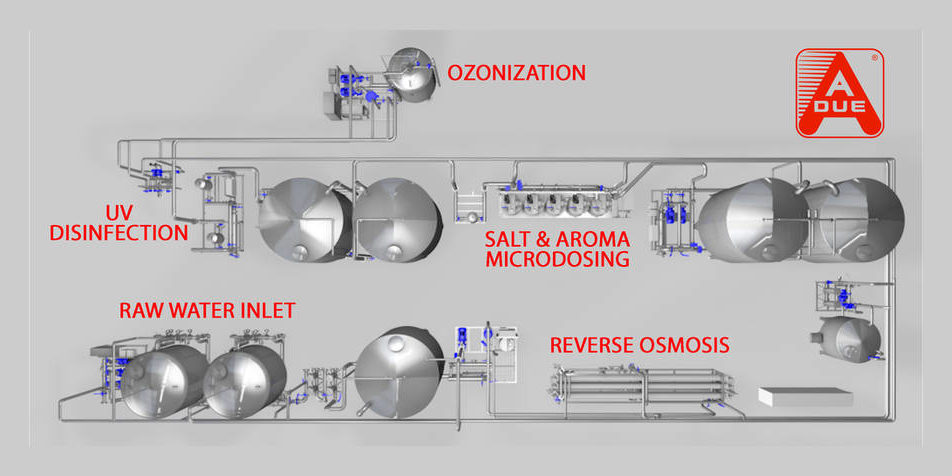

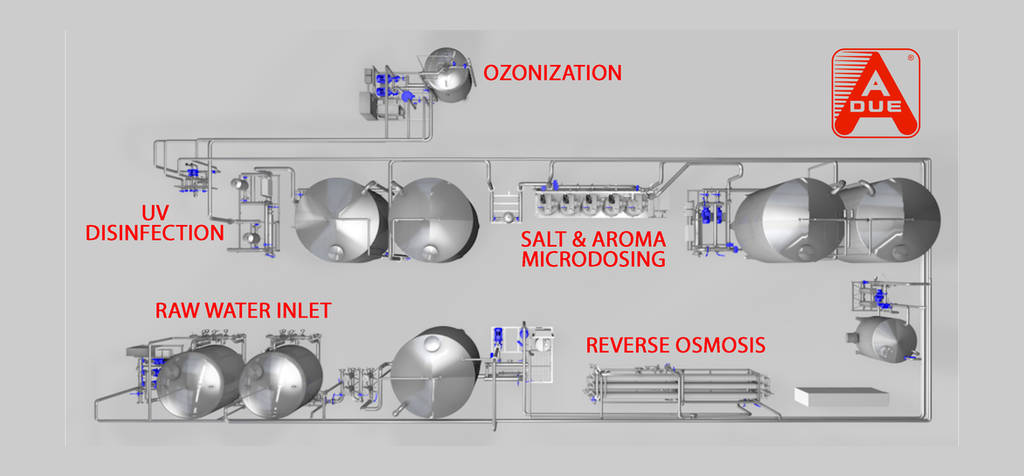

Usually the preparation of a functional drink involves water initial disinfection with subsequent filtration / microfiltration / ultrafiltration followed by a removal of the salts contained in the water by reverse osmosis (EASY.RO). Subsequently, according to the specific recipe, the in-line micro-dosing (EASY.RM) of the ingredients (mineral salts, vitamins, natural extracts, caffeine, taurine) and/or concentrated aromas is carried out, after which the final beverage undergoes sterilization with UV and / or Ozone (EASY.Ozone).

For the correct execution of the recipe, the preparation of solid and liquid ingredients, maximum dosage precision, process control and its traceability (EASY.Drive) are essential; always ensuring a quick flavour change-over and the waste reduction.

A DUE is able to manage all the preparation phases: the dosage, the dissolution, the mixing of several ingredients different by chemical nature (aromas, salts, acids, vitamins, natural extracts, lemon juice, sweeteners, milk or cocoa in powder), by physical state (powder, crystalline or liquid) or available with different containers (bag, drums, IBC, etc.).

The plant performs the dissolution of powder ingredients (acidifiers, functional salts, vitamins, etc.), the preparation of liquid ingredients (aromas, juices, semi-finished products, extracts, etc.), the controlled transfer of the concentrates and all ingredients into the preparation tanks.

The plant can be supplemented by a pasteurization system (EASY.Therm), if the drink needs to undergone a thermal treatment, and also by the CIP unit (EASY.Clean), for automatic sanitization with recovery.