The plant supplied by A DUE to one of the largest bottlers of Algeria is going to serve 3 aseptic filling lines and is able to prepare whole milk (through hydration of powdered milk), flavoured milk (with cocoa, coffee, strawberry, vanilla, etc.) and fruit juice with or without addition of milk.

At the project design stage the following key parameters were taken into account:

- commercial availability of the raw materials, in particular whole milk powder with 26% fat content, and skimmed milk powder with 1% fat content;

- chemical-physical composition of the raw materials (sugars, fats, proteins, vitamins, mineral salts) and the form (colloidal solution, emulsion, solution) in which the various components are present once dispersed in water;

- variables affecting the protein rehydration, such as: hardness and pH of the water used, process temperature, which must be optimized to avoid protein coagulation and obtain stable milk;

- the possible thermal treatment technologies suitable to destroy human pathogenic microorganisms and reduce microflora as much as possible, aimed at increasing the shelf life of the finished product. Two methods were analysed, based on a different combination of “time-temperature”: pasteurization and UHT treatment (Ultra High Temperature), in order to perform thermal treatment at high temperature and within the shortest possible time, to preserve the organoleptic characteristics and guarantee optimal results in terms of microbiology;

- the need of a de-aeration treatment upstream of the sterilizer in order to remove the air incorporated during the powder mixing and to prevent milk rancidity;

- the reduction of problems related to the effects resulting from the thermal treatment of sugars (lactose) and proteins: Maillard reaction, browning, caramelization of lactose; protein denaturation, with possible release of hydrogen sulfide;

- appropriate CIP cycle of the installation;

- the optimization of the plant layout to prevent (further to the pollution provoked by powder volatility) the other beverage preparation areas from contamination that can be caused by milk, being a source of allergens.

Therefore the process developed for the preparation of rehydrated milk involves the following steps: milk rehydration at 65°C, milk feeding to the sterilizer at 65°C, heating up to 80°C, de-aeration at 80 °C, transfer to the double-stage homogenizer at 80°C , 150 + 50 bar, sterilization up to 145°C for a few seconds, cooling down to 20°C and product delivery to the aseptic tank.

For the preparation of flavoured milk, rehydrated milk is added with sugar (in the case of sugary products) and flavourings (cocoa powder, coffee powder, vanilla, beta carotene, various fruit flavours) in the type and percentage determined by specific recipe, stabilizers to make the flavourings more stable (especially the cocoa that contains about 20% of insoluble residues). All of them prepared in special mixing areas. The mixing phase is followed by thermal treatment and homogenization.

For the preparation of fruit juices containing rehydrated milk, the first step is the milk rehydration, performed as described above. The rehydrated milk becomes an ingredient of fruit juice (10 ÷ 15% maximum content). Then the other ingredients are added: sugar, fruit concentrates, flavourings, etc.). The change of the product pH (3.5 ÷ 4.0, therefore with high acidity) implies the variation of the thermal treatment, which will be carried out at about 105 ÷ 110°C.

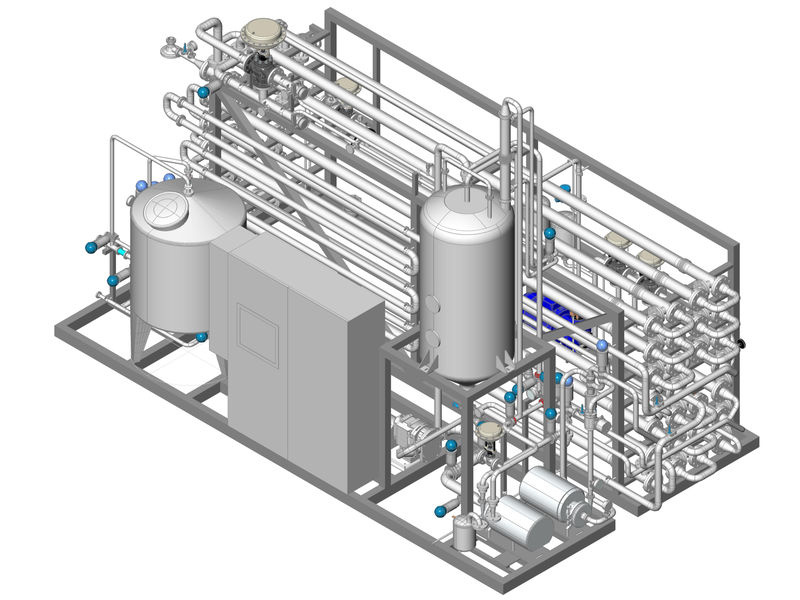

This system designed by A DUE in addition to the preparation tanks, plate and tubular heat exchanger, valve clusters, flavoured milk and fruit juice aseptic deaerator/pasteurizer, two-stage homogenizer, aseptic tank, is also provided with the powder dispersion system suitable for the powder ingredients such as cocoa, coffee, stabilizers, etc.

The system is completed by a general control panel and several local control panels for completely automatic management of recipes, recipe and alarm archives, historical trend management, event log.

A DUE can also offer its customers complete systems for the preparation of plant/vegan milks (such as soy, rice and almond milks) which are able to manage all the production phases: from the reception and storage of raw materials, dissolution and dosage of the ingredients, homogenization, up to the pasteurization of the finished product before bottling.

This is to meet the ever-increasingly demanding health needs of customers (lactose intolerance, high cholesterol, allergy to milk proteins), ethical-ideological requirements (vegan or vegetarian ideology, lower environmental impact), or to search for beverages with particular properties to satisfy specific nutritional or dietary needs.