HOW TO MAKE your ideal drink? Visit us @Drinktec

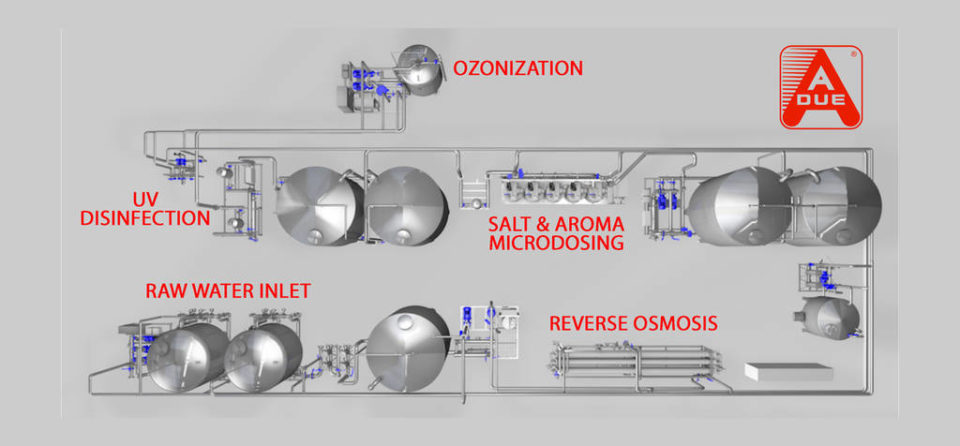

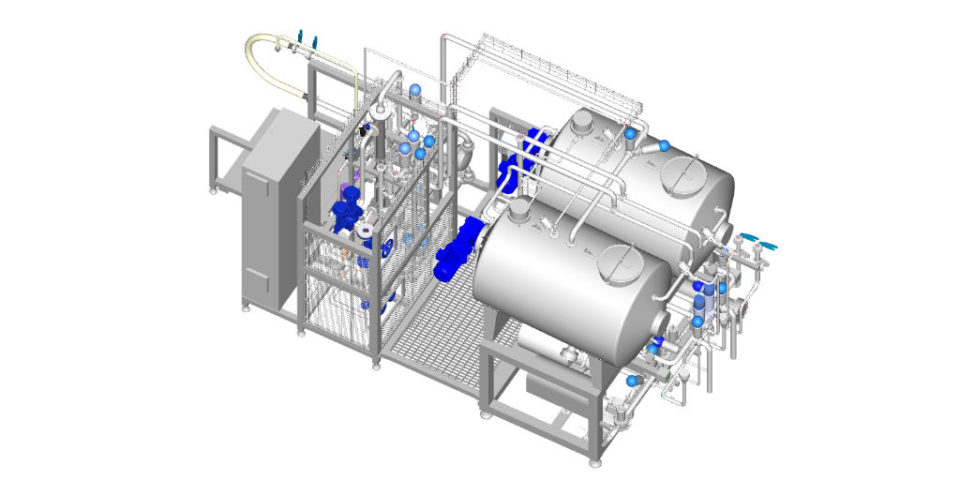

We will be present at Drinktec which will be held in Munich from 12th to 16th September. You will find us in Hall A6, stand 303, with innovative solutions able to guarantee the highest quality and safety of water and drinks. EASY.AirBox: the unit to purify air in contact with sensitive products and processes, protecting…